Typical $18,000 Plus Competition's Truck Mount's " POOR ENGINEERING"

This Single Grooved Pulley is Not Sufficient to carry the Load of a Blower this size. Which means Belt Slippage, Poor CFM Performance, Shortened life of the Belt & Definitely Breakage. There goes you jobs for the day!

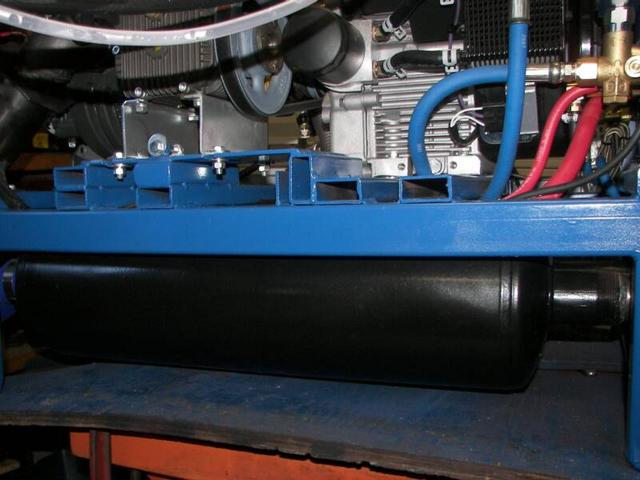

Blue Baron's Heavy Duty Belt Drive System

The Load is evenly distributed over the (2) Belts with increased surface area with our (BX) series Cog Belts giving better Grabbing ability.

This means Dependability with No Slippage or Breakage with Longer Belt Life that will keep on going through the Toughest Jobs Out- lasting the Competition.

Competition's Poor Blower Silencer Engineering

This manufacturer is attempting to save space, but they don't realize they are Diminishing CFM (Cubic Feet per minute) of air flow as a result of a Poor Internal Designed Silencer (Spiral arrangement of Baffels)

As a result, this obstructing of air flow will also Cause the Blower to OverHeat.

This equates to:

Poor Water Lift, Wet Carpets Drying too long means Unhappy Customer

Limits your jobs to the Length of your Vac Hose you can use

Shortened Blower Life

This manufacturer also attaches it silencer output to the inlet of the Heat Exchanger.

The sharing of these exhaust ports between the Silencer and the Engine can cause Damage to engine by causing excessive Back Pressure as well as overheated Blower & Engine, Poor Heat Transfer as well as CFM Performance.

Their idea of Mixing Hot Exhaust for the Engine and Blower Air makes no sense at all.

This "Major Design Flaw" Cancels Out the useful Heat Energy you need to Heat the Water.

Our Blue Baron Machines NEVER SHARE Engine Heat Exhaust with the Blower Exhaust Port.

In fact, Nothing is attached to our Blower except the silencer and our Engines are ONLY CONNECTED to their respective Axis Point Heat Exchangers.

RESULT: Both of these major Components are at the PEAK of their Performance!

Maximun HEAT & Maximun VACUUM!

Air Flow with NO OBSTRUCTION

Straight Through from the Blower Discharge Port to the front Exit Port of the Machine

MORE Details on this manufacturer's Poorly Designed Heat Exchanger System .

This manufacturer decided to put a Muffler before the Exhaust can enter the Heat Exchanger.

This equates to:

Loss of Useful Heat Energy because the Muffler not only obstructs the Flow of Exhaust (creating too much Back Pressure), but absorbs the Heat (Like a Radiator) that should be applied to the Heat Exchanger.

The Blue Baron Heat Exchanger is connected in a "Harmonious Design" from the Exhaust Header straight into a "Stream Lined" Stainless Exhaust Diverter straight into the Heat Exchanger and out the front of the machine.

This creates minimal back pressure, Instant Transfer of Exhaust Heat into the water and Long lasting Engine and Performance.

Our Heat Exchangers also take the place of the Muffler in Superior Dampening of Exhaust Noise from the engine.

These pictures came from a Customer that was in Desperate need of one on our Superior Heat Exchangers. This "Pricey Machine" accordingly to him, has already cost him (2) Engines & (1) Blower. This was due to the Inferior Engineering that this particular Manufacturer (without mentioning any names) produced. I am helping this customer Totally redesigned / reconstruct this machine so the same thing doesn't happen again.

We at Blue Baron Carpet Cleaning Systems, LLC, uphold to the Highest Standard of Engineering & Workmanship.

Each Exhaust Port / Pipe shown (Below) is Dedicate for it's own Specific Function.

The Larger Port is Only for the use of the Blower's discharge Vacuum air system (Superior CFM / Vacuum all the time)

This Exhaust Port is for the (No Heat)

Bypass Muffler where Exhaust Gases are rerouted through during Flood Jobs or where Heat is not required.

This Exhaust Port is for the Heat Exchangers and as mentioned before, not only Provides "State of the Art" Heating for the water, but acts as a Muffler for your engine providing Superior Noise Reduction.

Our Axis Point TM Heat Exchanger System is Unmatched in Engineering and Perfromance.

All Stainless Housing

3500 psi All Stainless Tubing

Axis Point TM Patented Design

for Quick Transfer of Heat

.....and our Competitions

Cheap Galvanized Steel Housing

prone to Rust

WEAK LOW PSI Copper Tubing

cannot withstand Pressures over 1000 psi

Poor Heat Transfer with Tubing to Close together

Exhaust Heat can reach all All areas of the Metal Tubing carrying the water

Cancellation of Heat by Blower Discharge Air

Proper Load Distribution where the Larger Pulley is on this Inside

of Crankshaft Closer to the Engine. This Lightens the Load on the Engine Shaft's Bearings and the Water Pump Belt is on the Outside for a Quick Change Out or replacement.